How Hungarian Automotive Can Harness The Power Of Electrification

2023. 05. 12.

High-ranking representatives of Hungary-based automotive stakeholders gathered for the ninth time to attend the 2023 edition of HIPA’s Automotive Conference, an annual flagship event of the Agency. Insights by top executives and renowned experts shed the light on how the transition to electrification shapes the present and the future of the sector, while elaborating on Hungary’s position in the process.

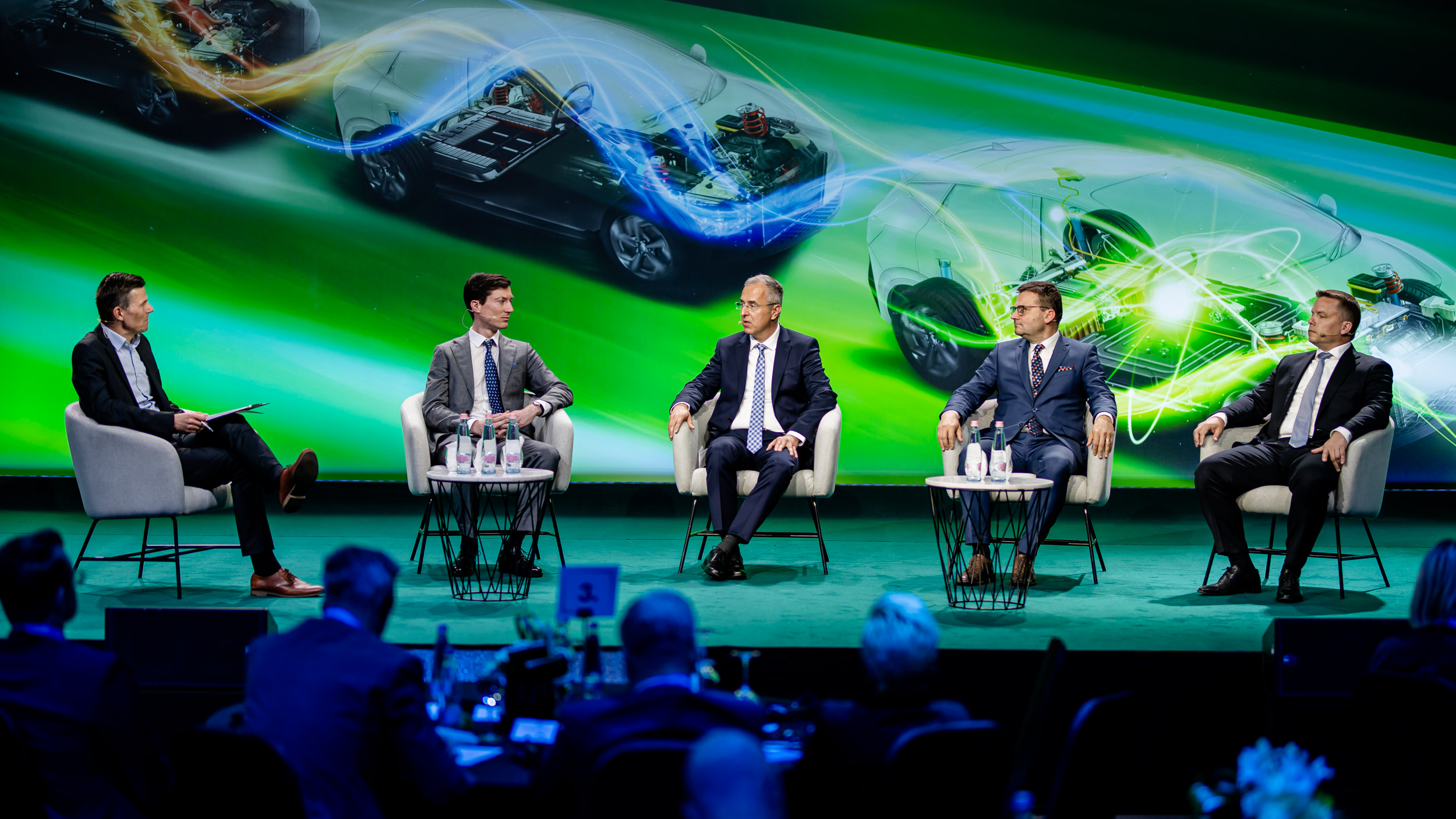

The car industry is disrupted by game-changing driving forces at unprecedented speed as the cars of the future will be connected, autonomous, shared and electric – also described altogether by the acronym CASE. The 2023 Automotive Conference of the Hungarian Investment Promotion Agency aimed to give a snapshot of the state-of-play of the sector, and over 150 participants had the opportunity to find out more about the latest trends with special regard to electrification. The annual gathering that was organized in association with the German-Hungarian Chamber of Industry and Commerce is the ultimate meeting point of senior automotive executives and industry experts in Hungary.

Hungary is a frontrunner of electrification

As Rita Szép-Tüske, HIPA’s deputy CEO for investment promotion and incentives pointed out in her opening speech, Hungary responded to the transition of the sector on time.

she said. Nothing less but Europe’s competitiveness is on the line here when we talk about the success of transition, Mrs. Szép-Tüske said.

Minister of Foreign Affairs and Trade Péter Szijjártó highlighted that high-level political decisions ushered the industry into a one-way street called electrification, while up to 90% of its key component, that is batteries, are produced by Asian companies – a big exposure, indeed.

he said, adding that Hungary aims to stick to the plan and is eager to keep her position based on the principle of connectivity.

It all comes down to sustainability

Top executives of Hungary-based OEMs discussed how they perceive these challenging times they face on the way to electrification, not least because they need to take into account the aspects of sustainability, profitability and competitiveness all at once, against the backdrop of stringent ESG requirements.

To BMW, sustainability is the most important factor of those three.

Eske Herrström, CFO of BMW Manufacturing Hungary Kft. explained.

It was agreed on part of the participants that the energy crisis actually helped accelerate changes to reach an ESG-proof operation.

Christian Wolff, managing director of Mercedes-Benz Manufacturing Hungary Kft. said, mentioning that as a response to the energy crisis they invested into technologies that reduced energy consumption. The company is starting its biggest transformation of its history, investing 1 billion in its Kecskemét plant. Mercedes-Benz will change the entire model portfolio of the existing plant, start building a second plant, and to back up the electric only strategy, they have just announced the building of a new battery assembly plant on their Kecskemét premises.

Services to the rescue

Challenging times call for ambitious measures, as is the case with Audi Hungaria. Chairman of the board Alfons Dintner emphasized how important it has become to further optimize processes and add new elements to their business portfolio, in the field of services in particular.

he added.

Suzuki had to weather the storm lately as well which resulted in profits dropping by half from 2021 to 2022 due to whopping energy bills, galloping wages and dire chip shortage. Still, optimism prevails on the group level.

László Urbán, deputy CEO of Magyar Suzuki Zrt. noted.

NIO is a newcomer and has a hard time to prevail on a market dominated by legacy firms. Yet, the Chinese company that runs battery swap stations and produces its own cars is dreaming big. At this point establishing a European network is what they find most difficult, Tibor Sőregi, NIO’s Head of European Power Manufacturing Technology Centre explained. But they can rely on a vast amount of data from their user base in China, and they are ready to replicate in Europe what they achieved at home: they have doubled the number of swap stations there since 2014 that total 1,300 by now.

In need of talent

Skilled labour was another hot topic addressed. The workforce needs to be training, and although competences with regard to conventional carmaking are available, AI-readiness and other cyber age skills are a long way to go, and so HIPA and government support is also needed to get workers to master those skills, Olívia Mesics, managing director of Opel Szentgotthárd Kft. pointed out.

she noted.

Speaking of labor shortage, Nevijo Mance, Managing Director of JLR Hungary Kft. added that if

China in the EV driver’s seat

Key trends of the industry were analyzed by András Kadocsa, partner at McKinsey & Company, in great detail on the basis of McKinsey’s market outlook. Although car sales have been dropping these past years, profitability has soared. The drop was supply-induced, not demand-driven, so the current record 7% operating profit is even expected to grow among top OEMs. On the other hand, on a global scale a return to historic peak-car sales are likely by the mid-2020s, depending on the degree of mobility disruption, Mr. Kadocsa highlighted.

He also emphasized the crucial role China plays in the EV revolution that was best showcased by the vast range of state-of-the-art EVs displayed at the latest Shangai Motor Show. The Asian giant’s EV market excels in many aspects, outshining the EU and the US in terms of growth, units and penetration. Chinese carmaker BYD further catches up to Tesla this year with over 150% YoY unit sales growth, although Tesla’s profitability remains ahead of other EV OEMs. In addition, China is and is expected to stay in the lead on battery production capacities (4,050 GWh by 2030) even if massive growth is to come in Europe (1,250 GWh) and North America (800 GWh) as well. As to different powertrain components, several potential growth opportunities are to consider in the EV segment, with battery cells being largest.

How suppliers can benefit from electrification

Experts shared insights at another roundtable discussion on how Hungary-based stakeholders adapt to the continuously changing requirements and constant market pressure to innovate. Hungary is turning into a battery manufacturing powerhouse; in fact, she ranks fourth in terms of battery production capacity in the world.

Market leading CATL that is setting up a plant for EUR 7.3 billion in Debrecen is an important pillar of this development. As company’s public affairs manager, Balázs Szilágyi explained, CATL has the most developed battery tech worldwide, and its latest condensed battery has been praised by many with reason. Having such corporate behemoths in the country has other advantages too.

he said.

Attila Szincsák, VP at DENSO Manufacturing Hungary Ltd. stressed that the EU-level internal combustion engine (ICE) ban might be set in stone, but traffic-induced air pollution is responsible only for a fraction of total emissions. Decision makers therefore should rather focus on how to eliminate the rest, because the ban itself doesn’t solve the majority of climate change-related problems.

he said.

No matter what, István Németh, managing director at Cascade Engineering Europe Kft. believes that we are at an early stage of electrification which has a vast potential.

Mr. Németh concluded.

Hands-off is not quite here yet

Automotive is also undergoing a shift from ownership to usership. Therefore, software has become the product that makes or breaks a business. According to Gábor Pongrácz, head of engineering and R&D at aiMotive, it is hard to throw software onto legacy architectures as continuous updating is by far not default setting in this case.

he said, adding that one of the reasons why autonomous driving developments have stalled has to do with regulation, or rather the lack of it, as the market is still awaiting a comprehensive set of rules on the European level that can help speed up the proliferation of the technology.

Related articles

Sector articles

On the 15th anniversary of Stadler’s Szolnok facility, the first aluminum double-decker car body produced in Jász-Nagykun-Szolnok County was unveiled. This milestone was achieved as part of an EUR 45.2 million investment launched in 2023, enabling the Szolnok pl...

2025. 01. 17.

Automotive #AutomotiveFeintool, a Swiss-owned leader in precision electrical steel and formed steel components manufacturing, is investing EUR 34.1 million to expand its Tokod facility in Hungary’s Esztergom district. The project will add 6,740 square meters to the existing plant, wi...

2024. 12. 17.

Automotive #AutomotiveChinese electric car manufacturer BYD first Hungarian Suppliers' Forum in Budapest attracted more than hundred domestic companies. At the two-day event, organised by HIPA Hungarian Investment Promotion Agency, Minister of Foreign Affairs and Trade Péter Szijjárt...

2024. 10. 16.

Automotive #Automotive